Wear and tear of rails by trains is inevitable.

So how should these used rails be handled? Can they be recycled and reused?

High-speed rail lines must also be maintained regularly. The stability of the steel rails and the flatness of the rails by high-speed rail trains must be controlled within 1 mm, otherwise vibrations will occur during operation. So if it is found that the wear of a certain section of rails exceeds the standard, the engineering personnel will be notified to dismantle and replace it. And the rails dismantled every year are not a small amount.

Most people would think that these steel rails will be recycled, which will not only reduce the cost of making new rails, but also recycle steel resources. But in fact, these rails will be scrapped directly, because the manufacturing process used by the existing rails is not remelted by ordinary factories, and only high-priced electric furnace equipment can be purchased to recast. But this not only consumes a lot of electricity resources, but also increases transportation and storage costs.

In addition, it is also a major technical problem. At present, the technology for secondary processing of rails is not very mature. If you blindly try to reprocess the used rails, the final result is likely to be more costly than gain. Therefore, recycling and reuse is unrealistic.

So are these used rails thrown away directly? Not really.

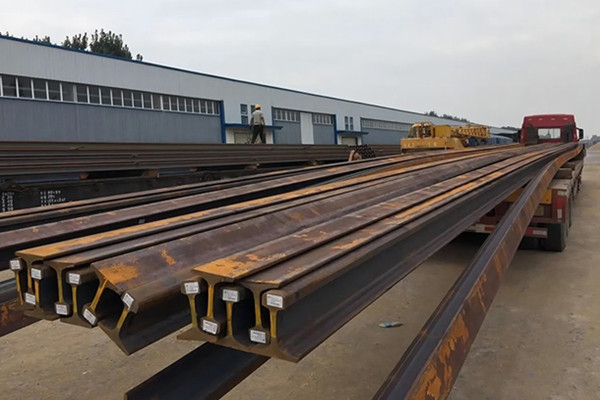

After all, these rails are special steels made by the country, and they are made of good materials. They are not easy to rust in the open air, and can withstand hundreds of tons of weight without deformation. Therefore, of course, these scrapped steels will not be piled up in the garbage dump to corrode. Generally, two methods are used to deal with this type of steel.

The first is to temporarily store these rails in the station. If an emergency occurs, they can be taken out and used as temporary spare rails. Another method is to use them to manufacture other special equipment, such as giant cranes in steel mills. Although the cost of recasting the rails is high, the manufacturing cost of these special equipment is also high, which is enough to balance the cost of recasting the rails.

Get In Touch